FAQ

What are Mountain Laurel Handrails?

Mountain laurel handrails are a traditional form of artistic expression that I discovered while living in the Smoky Mountains of Western North Carolina. These handrails use the branches of the mountain laurel tree which are naturally curved in wonderful shapes.

Click this link to watch a video about What are Mountain Laurel Handrails?

How are they made?

Handrails are typically made with a red cedar 2×4 board on the top and bottom. Mountain laurel sticks are fastened to these boards and woven together with each other.

What are preassembled handrail sections?

Preassembled sections arrive ready-to-install. The handrail sections are one side of boards with the mountain laurel sticks attached. The boards on the other side and the top handrail are installed on site. This is so that your installer can hide fasteners in the railing.

How do I place an order for Mountain Laurel Handrails?

All orders are custom made according to your specifications. Email me with the information outlined below at info@awoodrailing.com, or call me at 828-342-0873 to discuss your personal project needs.

To complete your order, please provide:

- Name

- Delivery Address

- Delivery Phone Number

- Lumber Type — typically smooth western red cedar

- Lumber Dimensions — typically 1×4 or 2×4 depending on post dimensions

- Finish Type — Paint, Stain or Unfinished

- Finish Manufacturer

- Finish Color

- Regular Section Lengths

- Regular Section Height

- Stairs Section Lengths

- Stairs Section Height

- Stairs Section Angle

- Stairs Section Side of Stairs

Do you speak Spanish?

Si, se habla español.

Do you deliver?

Yes, delivery is available nationwide. Delivery is made via a full-size 53′ tractor-trailer. Please ensure that your address is accessible to a vehicle of this size.

Delivery is usually to a residence. Larger orders can require access to a loading dock and forklift or orders may be picked up at a local freight terminal.

Delivery cost varies with the size of the order. All shipping crates are custom built to fit the specific order.

For large orders of more than one crate, I recommend receiving delivery at a location equipped with a loading dock and forklift. This will give you time to dismantle the crates at your leisure. Delivery can also be received at a local freight terminal if you have access to a trailer.

Before signing to accept delivery, please inspect the contents of your package carefully. If there is any damage, document it with multiple pictures showing the delivery truck if possible. Make sure that the driver notes the damage on the receipt before you sign. If you believe the damage is irreparable, please call immediately before taking any other action.

How much do your railings cost?

Each railing order is unique. Cost depends on many variables including quantity, delivery destination and optional upgrades. Prices start at $90/lf plus shipping.

What is the return policy?

Due to the custom nature of the work, no returns are accepted and there are no refunds.

How long does it take to receive my order?

This depends on the size of the order, current production schedule, and other factors like special order lumber or paint/stain. It’s typically four weeks from when we finalize your order to when we ship.

Who does the installation?

Your handrails arrive ready-to-install. Installing wood railings requires basic carpentry skills like cutting boards and driving screws. Installation is best performed by a skilled carpenter. We work closely with your chosen installer to ensure a perfect fit!

Are there installation instructions?

- Remove sections from package<

- Place 2×4 blocks on edge by posts

- Place sections on blocks by posts

- Mark ends of sections and cut to fit

- Slide sections into place

- Screw to post with appropriate size screw

- Cut 2x4s (not included) to size

- Use finish nail gun to nail 2×4 into fatter diameter sticks

- Screw or nail 2×4 to posts

- Cut 2×6 top cap (not included) to length

- Use trim head screws and angle upwards through the 2×4s into the bottom of the 2×6 for a fastener free top

- Also screw the 2×6 into the posts as possible

See the Installation Instructions

Does the railing meet building code?

Building code varies by jurisdiction and can be very different from one place to the next. All railing sections are built such that no opening is greater than 4″ sphere, a common building code requirement. Sections are also built to withstand a 50 pounds/square foot force, another common code requirement. Typical section height of 31″ plus 3.5″ clearance from floor plus 2×6 top plate yields 36″ finish height.

What sort of maintenance is required?

The railings require little maintenance. The branches will weather to a silver color that is similar to a piece of weathered cedar. If you want to preserve the original reddish color of the sticks, we can apply a natural stain to the sticks here in the shop.

Will this product hold up to harsh weather?

I started building handrails with mountain laurel in 2004 after seeing installations that were 25+ years old. Laurel is a dense wood that handles weather well. The area where this style originates, in and around Highlands, NC, is considered a rainforest for an average 90″ of rain per year.

Can my railings be painted or stained?

Paint or stain on the lumber for the top and bottom rails is included in the price of the typical project. You select the stain and we get the same product to match what you’re already using. A typical choice is to match the same color as the posts or window and door casings. Click here for an image of different kinds of stain on red cedar and white pine lumber.

Though generally left unfinished, railings can also have sticks painted or stained as an optional upgrade.

What about a sealer, like poly or varnish?

I generally recommend against using any kind of poly or varnish on the sticks outside. The finish will always start to weather well before the sticks. First it yellows then it starts to flake and peel. If you want to maintain the natural red color of the sticks, we can apply a natural stain in the shop. This is a clear stain that is also a penetrating sealer. Stain will have to be reapplied to maintain the color.

What type of wood do you use?

Typical lumber is smooth western red cedar 2×4 or 1×4. Multiple different options are available: rough sawn cedar, rough sawn pine, cypress, oak, yellow pine, black locust, barn wood, ipe, teak, pretty much any wood that is available as a board can be used in the typical design.

Branches used for balusters are mountain laurel, Kalmia latifolia.

Are there other options?

The top and bottom pieces can be round logs and the mountain laurel branches can be fastened to the round logs by either mortise and tenon joints or by flush cutting the sticks and nailing. Common wood species for the round logs include pine, poplar and black locust. Mortise and tenon joinery is recommended for interior use only to avoid collecting water in the bottom mortises.

What other products can you make?

Mountain Laurel Furniture comes in all shapes, sizes and styles including: framed mountain laurel art pieces, rustic headboards, coffee tables, side tables, end tables, sofa tables, framed mirrors, benches chairs, magazine racks, and pretty much any item you can think of. We’ve made a custom nightstand that is also a dog bed.

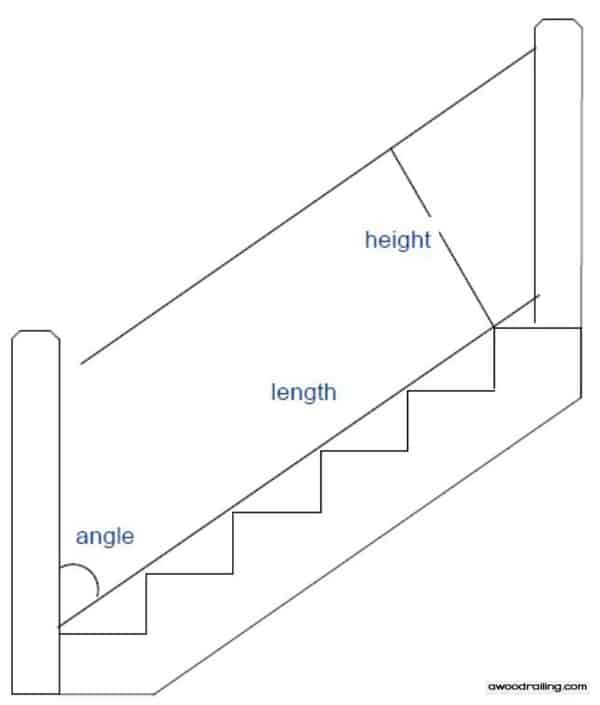

How do I measure for stair railing?

The best way to measure the height of the stair railing section is to have the posts installed. Clamp a 2×4 to the level sections with the top at the bottom of the top 2×6. Mark the newel post on top of the stairs. Set a 2x on the leading edge of the tread. Measure the height from the board to the mark. Use this number and measure and make a mark on the bottom newel. Use a framing square to measure perpendicular to the angle of the stairs, either to the leading edge of the tread or the side of the stringer. Use the 2x set on the leading edge of the tread to measure the section length and angle in degrees.

Here’s a drawing showing how to measure for stairs

Are there CAD drawings or symbols to use in architectural plans or renderings?

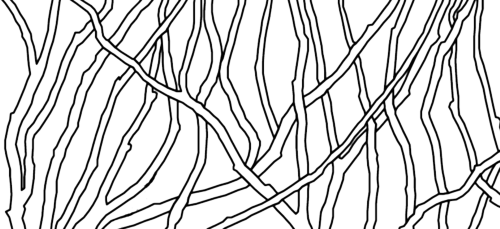

Architects and designers can use these drawings to easily incorporate Mountain Laurel Handrail into the wood deck plans. Rendering Mountain Laurel Handrails in 3D modeling software can be difficult due to the complexity of the shapes in these rustic branch and twig railings. The picture below can be used in 2D elevations and sections of the architectural drawings to help get a feel for how the handrails will look.

These files (Instant Download – 4.6 MB) are in the .3ds format which is used commonly by different programs. They are fully stretchable and modifiable 3D symbols for use in most architecture.

The image below can be used in elevation drawings in plan sets. Just right click it and hit save as to download to local.

Can I buy mountain laurel stick bundles for railing parts?

Mountain Laurel Material is sold in bundles of 10 sticks, 8′ long, 0.5″ to 1.5″ diameter

Price per bundle is $240 and shipping is additional.

You get about 6.5 feet of railing per bundle.

What types of payment do you accept?

We accept payment via credit card online, check by mail, or ACH payments.

What if the area I need railings for is curved?

We can build curved railings. Please see

prices for curved railings start at $130/lf plus $350 jig setup fee.

Once your posts are installed, you can provide measurements from post to post along with standoff measurements approx every foot.

Can I pick up my railings instead of having them delivered?

Yes. Local pickup is available during normal business hours, Monday to Friday, 10AM to 5PM.

Please make an appointment at least 48 hours in advance. The pickup location is our workshop located in Franklin, NC.

Is there bark on the mountain laurel branches?

Sticks are typically left just the way the come from the forest for the most rustic look. Some people like the sticks cleaned to remove the loose bark and moss and lichen. Cost for this is $10 per linear foot. This is different than removing the bark from sticks.

How do I select my stain or paint color?

Paint or stain on the cedar 2×4 lumber is included in the price of the typical project. You select the stain and we get the same product to match what you’re already using. A typical choice is to match the same color as the posts or window and door casings. Here is a link that shows some different kinds of stain on red cedar and white pine lumber.